|

Materials used in piston are composed of a special aluminum alloy and some other metal elements. They change into sophisticated products after going through different phases and meeting international standards like ISO/TS 16949 and are offered to AM and OEM market customers. Increasing power and acceleration in modern engines imposes high heat and tension on pistons. On the other hand, designers of gasoline and diesel engines are faced with challenges like reducing air pollution, increasing density, and higher efficiency for fuel and oil; consequently, pistons used in such engines require maximum solidity and minimum weight. IPMCo’s new generation of piston is designed and produced to meet engine manufacturers’ demands.

Different Phases of Production :

Casting: After being melted and combined with some metal elements in pre-melting, inductive, and electric holding furnaces, pure aluminum bar is converted into a special alloy for casting raw piston. By means of modern equipments like quantometers (with micron precision capability), quality control labs and conducting various experiments like vacuum tests and temperature analyses, melted materials are improved and prepared for gravity-casting in steel moulds. Finally, after thermal operations, ultrasonic, hardness and appearance control, the cast raw piston is ready for turning phase in Machine shop unit.

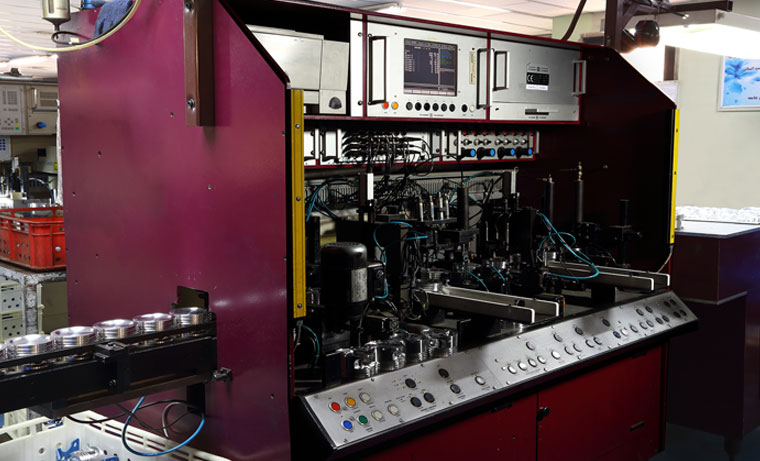

Machining (Machine shop): Utilization of modern automatic and semi-automatic CNC machineries in different production lines has made the production and machining of any type of piston of a diameter up to 150 mm possible in IPMCo. Fully automatic piston movements, robotic charging and discharging of the part off all the machineries, precision, quality, production capacity and variety have given IPMCo a unique standing in the world. In this phase, surface and every corner of piston including body, front, pin’s hole and groove, rings’ grooves, combustion chamber, profile and valve pockets are rough-machined and finished.

In each of the above mentioned processes, testing is implemented by means of self-control and test equipments.

Washing: To ensure that excess particles caused by machining procedures are removed from the piston, in a special temperature, high precision washing using ultrasonic and spray systems and detergents is carried out.

Final control: All products go through dimensional and geometrical control processes.

Phosphating: In this phase, pistons are prepared for coating.

Coating & Covering: Coverage of tin and graphite decreases friction and improves corrosion and wear resistance. This will stop engine from having a piston failure in critical conditions. In the last phase of production, various petrol and diesel engine pistons are covered with tin and graphite using spray or Silkscreen method.

|